OK be warned... , This is one of the most unattractive end result projects I've ever done . But, it saved a wad of cash and since the only things viewing the seat are cows and Dixie the collie, I am happy to save $$$. I got everything from a mazon

So here goes.... First mistake was choosing light gray vinyl. It was on special so I got weak and chose it.. shoulda been the dark gray. it would have been so much better then and hidden some of the puppy foot prints and my errors.

I detached the seat from the RTV and made a shallow cut around the edges of the old vinyl with a utility knife.Then the old vinyl just peeled off (like a tangerine . Then I tried to fill in a little hole in the foam with some other foam pieces I had- Its better not to procrastinate this job because the sunlight will quickly break down the old seat's exposed foam. It just sorta rots - quickly too - There was a large hole right where I sit to drive and Dixie would always put her rear foot in it for traction - that helped "waller" it out .

. Then I tried to fill in a little hole in the foam with some other foam pieces I had- Its better not to procrastinate this job because the sunlight will quickly break down the old seat's exposed foam. It just sorta rots - quickly too - There was a large hole right where I sit to drive and Dixie would always put her rear foot in it for traction - that helped "waller" it out .

I measured 3 x and cut the material- leaving a little extra pays off . Since I was also using a foam spray adhesive I made some marks so I would start with the material centered.

I worked from back to front and slowly and firmly spread the vinyl over the tacky contact cement as I brought it to me.. Go slow because that 3M foam contact cement is some good stuff.

2nd mistake I made was spraying the whole seat and entire piece of replacement vinyl . I should have left the corners for doing one at a time because as I was folding the vinyl over towards me and got to the corners, the vinyl end folds met and were good and stuck but to each other not the foam.. .

I used my Arrow staple gun and tacked down the edges to the underside. I also sprayed some of the adhesive to the area before stapling.

$12.50 for the rather thick yet soft vinyl plus the on sale- $7.50 can of adhesive, I have a dry place to sit and not worry about the puppy dog and her toenails. It's ok for a working farm RTV but not for a fancy one and yes, I'd get a factory seat if I was gonna sell it but I'm not so have $240 saved.

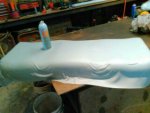

In picture #4, the one with the seat on the worktable , the wrinkled up material in view is an old sheet to help keep grease and grime off of the new material whick is shown in the same picture flipped over and with the adhesive sprayed on it. Then, I pulled it back and sprayed the foam. That is a good quality adhesive !. And that's Dixie (aka leg breaker because she falls off of everything) hence the very short chained safety vest when in motion which is short so she won't have the length to fall off and be dragged) ... Yea,, had to go to MSU to get that leg fixed...... Now I'm reducing chances all I can so she does wear her safety vest when in motion and no 4 whlr - no way.

https://amazon.com/gp/product/B01E5YEXGS/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

3M Foam & Fabric 24 Spray Adhesive Orange, 20 fl Ounce can, Net Weight 13.75 Ounce

bordercollie

So here goes.... First mistake was choosing light gray vinyl. It was on special so I got weak and chose it.. shoulda been the dark gray. it would have been so much better then and hidden some of the puppy foot prints and my errors.

I detached the seat from the RTV and made a shallow cut around the edges of the old vinyl with a utility knife.Then the old vinyl just peeled off (like a tangerine

I measured 3 x and cut the material- leaving a little extra pays off . Since I was also using a foam spray adhesive I made some marks so I would start with the material centered.

I worked from back to front and slowly and firmly spread the vinyl over the tacky contact cement as I brought it to me.. Go slow because that 3M foam contact cement is some good stuff.

2nd mistake I made was spraying the whole seat and entire piece of replacement vinyl . I should have left the corners for doing one at a time because as I was folding the vinyl over towards me and got to the corners, the vinyl end folds met and were good and stuck but to each other not the foam.. .

I used my Arrow staple gun and tacked down the edges to the underside. I also sprayed some of the adhesive to the area before stapling.

$12.50 for the rather thick yet soft vinyl plus the on sale- $7.50 can of adhesive, I have a dry place to sit and not worry about the puppy dog and her toenails. It's ok for a working farm RTV but not for a fancy one and yes, I'd get a factory seat if I was gonna sell it but I'm not so have $240 saved.

In picture #4, the one with the seat on the worktable , the wrinkled up material in view is an old sheet to help keep grease and grime off of the new material whick is shown in the same picture flipped over and with the adhesive sprayed on it. Then, I pulled it back and sprayed the foam. That is a good quality adhesive !. And that's Dixie (aka leg breaker because she falls off of everything) hence the very short chained safety vest when in motion which is short so she won't have the length to fall off and be dragged) ... Yea,, had to go to MSU to get that leg fixed...... Now I'm reducing chances all I can so she does wear her safety vest when in motion and no 4 whlr - no way.

https://amazon.com/gp/product/B01E5YEXGS/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

3M Foam & Fabric 24 Spray Adhesive Orange, 20 fl Ounce can, Net Weight 13.75 Ounce

bordercollie

Attachments

Last edited: