Finally decided to stop messing about and make a proper project, a tractor....

Going for 4WD articulated, all hydraulic.

Bought 4 wheel motors and some steel and away I go. I'm buying the other bits as I get decent prices on them, steering valve should be coming this week, might look into pumps next week.

Pic 1 - rough chassis design

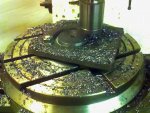

Pic 2 - hydraulic motor and mount plate

Pic 3 - rear axle unit

Going for 4WD articulated, all hydraulic.

Bought 4 wheel motors and some steel and away I go. I'm buying the other bits as I get decent prices on them, steering valve should be coming this week, might look into pumps next week.

Pic 1 - rough chassis design

Pic 2 - hydraulic motor and mount plate

Pic 3 - rear axle unit