For people who see this thread looking for answers, I copied and pasted my findings here from my other thread.

OK, here's the update. Just finished up the turbo installation and fueling adjustments. Also did the HST optimization procedure and adjusted the charge pressure and the high pressure relief.

As for the fueling adjustments I made, and as a reference to my other thread asking what the 3 adjustment screws are and what they do, I will try to explain it here.

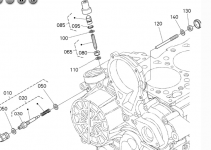

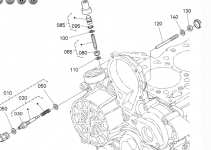

Screw #20 = Fuel Rack Limit adjustment - Limits how far the fuel rack can be pushed by the governor under load when the RPM drops. Right now I am at 1 turn out from the factory setting and there is slight smoke under load. May adjust further out as I get more hours on it and get a better feel for it.

Screw #65 = Max Fuel adjustment - This screw limits the max amount of fuel the injection pump will deliver. I have no idea as to where the factory setting was. When I finally got the tamper proff sleeve off, the screw and jam nut were loose. I set the screw to 0.650" from end of screw to copper washer as one set of the instructions states. These instructions say that adjustments are case-by-case and even though the machine is running great right now, I'm sure I will adjust it further out as I go.

Screw #120 = Intermediate Governor Screw. I'm really not sure what this does yet. In one set of instructions it said to back it out 2 1/2 turns so thats what I did.

I also advance the injection timing about 2 degrees by taking out the thinnist shim. I feel I could advance it another 2+ degrees but I was left with only 1 shim, which is the thickest one with no holes so I left it in place.

I adjusted the charge pressure in 1 turn as set of instructions said to turn it in 1 to 2 turns. I went one turn but as of now, I do not have s set of Test Guages so in the future I will turn it in some more when I get guages. I really didn't notice any change in HST performance but for whatever reason, shifting from high to low to reverse is much, much smoother. No more stomping brake and tapping the throttle to get it to shift. It is smooth. Not really sure what made it smoother but I like it.

I also adjusted the high pressure relief and turned it in about 3/4 of a turn. Again, no real noticable difference. Again, when I get some test guages, I will revisit the HST adjustments.

As for the turbo installation, I can say this was a really nice and well thought out kit. It was from turbokits.com and actually went together smoothly. The engine bay does get pretty tight and the hardest part was figuring out how to get the nuts and bolts tightend up on the exhaust manifold, turbine housing to exhuast manifold, and a few other places. It trial and error, tighten down this and loosen it up again to tighten something else. It was a bit frustrating at times but get creative and you can figure out how to get it all tightened down.

As for the fueling and HST adjustments, I took instruction from 3 different kits and did all the adjustments they all stated to do. I believe adjusting everything made a huge difference. The machine runs amazingly well and the difference it quite noticable. Like I said, I will continue to make adjustments as I go and get a better feel for it in a working environment but in the brief testing I did last night, all was perfect and well within the parameters I was expecting. Here are my findings.

EGT's never got above 900 degrees. I was not loading the engine to its full ptotential by any means, but I feel with EGT's that low, I can up the max fueling quite a bit yet.

Water and oil temps never got above 180 degrees. Again, it was 20 degrees outside and I was not loading the machine to it's max and only ran 3 miles in the brief preliminary testing last night.

Boost was running about 5 PSI at full throttle in neutral. On the road, at full throttle I was seeing 9 PSI. Again, this is just the machine driving down the road and not putting a real load on the engine. I am guessing by loading the engine, I will see 12+ PSI but that is specualtion at this point and more tuning/testing will be done.

Here's the best part. THE SOUND! It took about 20 minutes for the turbine to "break in" if that is the correct term. For the first few starts and tests, the turbine would only spool up at about half throttle, at least the the point where you could hear it. At low idle, 1500 RPM, it was not producing any boost which I expected. After about 20 minutes of running the engine and keeping an eye temps and smoke levels etc. the turbo seemed to "loosen up" and was whistling at low idle. Right now, it is making 0.75 - 1.0 PSI of boost at 1500 RPM which is surprising to me. It does sound awesome though. The short open muffler connected to the short downpipe really lets the whistle come through in the exhaust note. It makes me smile just listening to it. At full throttle it sounds like a jet engine. I am no stranger to turbo diesels and even though my F350 is deleted, big turbo, tuned to the max, 5" straight exhaust with no muffler, and making about 700 HP, this little Kubota sounds better! Im chalking this project up as a BIG WIN!