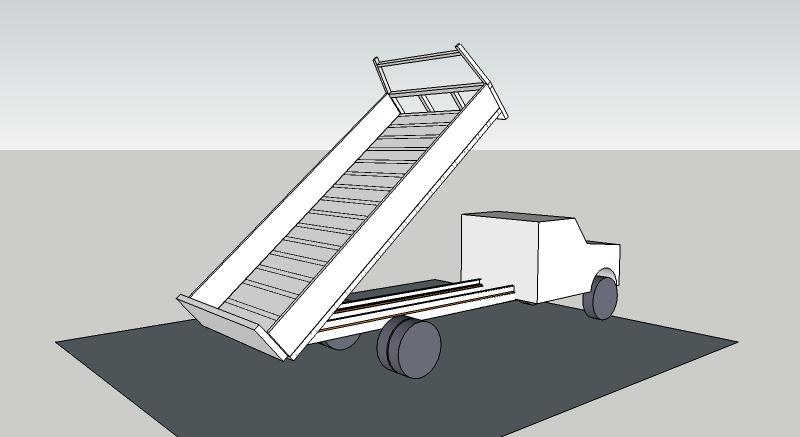

Just wanted to post some pictures of a project I am working on. Picked up a 2000 F550 16' Box truck. It is rated 19000 gvw. Plan is to convert it to a flatbed dump. I have picked up a cheap flatbed and scissor hoist from a topkick for it. So far, I am into it (3.5k) for less than most people have in a new gooseneck trailer. Plan to use it for odds-n-ends, carrying wood, cars, tractor, etc...

The beginning...Truck was a little sick when I bought it. It has the 7.3PSD with 250k miles. Couldn't go over 50mph on flat road. I've rebuilt the turbo (easy) and removed the EBPV, replaced the downpipes and fixed all the turbo pressure leaks. Now it can keep speed and sounds good, but still not 100%, scanner tells me injector 8 is bad and also a high pressure oil leak. If anybody knows about these PSD engines, I could use some tips to narrow down the high pressure oil leak.

Sold and removed the box about 3 weeks ago. With some cribbing, bottle jacks and 55 gal drums, I raised it up enough to drive out from under it. With the box off, it drove like a sportscar with no suspension.

Next step is to make a subframe for the flatbed out of some 4 or 6 inch channel, this raises the bed some to help with the overhang when dumping, gives me more room for the hoist, strengthens the truck frame and allows it to be removable with a few ubolts.

This is were I am at right now, in next couple weeks I hope to get the flatbed on the truck but without hydraulics hooked up. Later on, a bumper and hitch setup.

The beginning...Truck was a little sick when I bought it. It has the 7.3PSD with 250k miles. Couldn't go over 50mph on flat road. I've rebuilt the turbo (easy) and removed the EBPV, replaced the downpipes and fixed all the turbo pressure leaks. Now it can keep speed and sounds good, but still not 100%, scanner tells me injector 8 is bad and also a high pressure oil leak. If anybody knows about these PSD engines, I could use some tips to narrow down the high pressure oil leak.

Sold and removed the box about 3 weeks ago. With some cribbing, bottle jacks and 55 gal drums, I raised it up enough to drive out from under it. With the box off, it drove like a sportscar with no suspension.

Next step is to make a subframe for the flatbed out of some 4 or 6 inch channel, this raises the bed some to help with the overhang when dumping, gives me more room for the hoist, strengthens the truck frame and allows it to be removable with a few ubolts.

This is were I am at right now, in next couple weeks I hope to get the flatbed on the truck but without hydraulics hooked up. Later on, a bumper and hitch setup.

. Heres a pic of My 53 chevy yard truck I use for moving dirt around the property .

. Heres a pic of My 53 chevy yard truck I use for moving dirt around the property .  , but I have a 54 chevy as well I,m restoring & its an Original steel framed wooden flatbed dump bed & the woods all shot I,m sure i,ll need some help when I get around to rebuilding it to all steel . Thanks , an interesting thread .

, but I have a 54 chevy as well I,m restoring & its an Original steel framed wooden flatbed dump bed & the woods all shot I,m sure i,ll need some help when I get around to rebuilding it to all steel . Thanks , an interesting thread .  Bob

Bob