I have read through all 22 pages of the all thread “kubota-rtv-900 transmission problems” which has been very informative.

The machine came to me not moving at all and the driver had said it had got stuck in gear and they had removed the selector and corrected this. I am not sure if this mistaken.

I am fairly sure the problem lies in the HST as the input shaft it connected to the engine, as the auxiliary hydraulics still work. On the output side I can see the shafts in the gearbox turn when the wheel is turned when looking into the selector.

The linkage is all working and the shaft on the servo control rotates as it should. To me it seems as if the piston is not moving the swash plate and I guess the first think to check is the charge pressure. The fault is absolutely complete, no attempt to rotate the wheel even when jacked up.

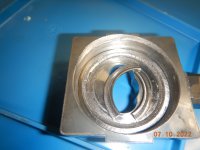

I have pressure gauges and was attempting to check the charge pressure but I have rounded the allen socket on the ¼ BSPP plug which I think is the correct one, the middle of 3 on the RHS of the Port Block cover.

I have referred to a WSM addendum for a new transmission issued in 2006 and although very good on the operation and looks as if the transmission has not changed much, it has no guidance on dismantling the HST.

-So can anyone point me in the direction of a better manual available in UK?

- Dvaepat4 referred to a local trader who could supply parts in Scotland, I am in Cumbria so would be good to know the trader, that might be the source of the correct WSM.

- Any ideas of what might have happened?

- Is there more than one place the charge pressure can be measured and was I on the only correct plug that I cannot get out now, unless I dismantle?

Look forward to hearing form anyone who may be able to point me in the right direction.

The machine came to me not moving at all and the driver had said it had got stuck in gear and they had removed the selector and corrected this. I am not sure if this mistaken.

I am fairly sure the problem lies in the HST as the input shaft it connected to the engine, as the auxiliary hydraulics still work. On the output side I can see the shafts in the gearbox turn when the wheel is turned when looking into the selector.

The linkage is all working and the shaft on the servo control rotates as it should. To me it seems as if the piston is not moving the swash plate and I guess the first think to check is the charge pressure. The fault is absolutely complete, no attempt to rotate the wheel even when jacked up.

I have pressure gauges and was attempting to check the charge pressure but I have rounded the allen socket on the ¼ BSPP plug which I think is the correct one, the middle of 3 on the RHS of the Port Block cover.

I have referred to a WSM addendum for a new transmission issued in 2006 and although very good on the operation and looks as if the transmission has not changed much, it has no guidance on dismantling the HST.

-So can anyone point me in the direction of a better manual available in UK?

- Dvaepat4 referred to a local trader who could supply parts in Scotland, I am in Cumbria so would be good to know the trader, that might be the source of the correct WSM.

- Any ideas of what might have happened?

- Is there more than one place the charge pressure can be measured and was I on the only correct plug that I cannot get out now, unless I dismantle?

Look forward to hearing form anyone who may be able to point me in the right direction.