Hey Guys and Gals,

I recently acquired an old GT garden tractor of the late ‘60’s early ‘70’s era. It’s an SS-12 Sears.

My original intentions were to restore the little tractor just for fun but the previous owner did some troublesome and moderately malicious ‘butchering’ while replacing the original Tecumseh 12 HP with a side valve, 10 HP Honda. The frame was the original engine mount with pre-drilled holes to accommodate the stock engine but….Bits were cut with a torch for (unnecessary) clearances and other misaligned, but now, near permanent welds have repositioned the pulley travel-clutch mechanism and engine motor mount plate (also slightly misaligned). This caused the crankshaft pulley to be forever at a kilter to the rest of the pulley drive system….Clear as MUD? ....LOL.

....LOL.

OK, just skip everything I said above and understand that I spent several hours with various grinders and cut-off tools to carefully UNDO everything! I am now free to properly locate the correct distances, angles and height of the new (replacement) engine. Only one small problem, this engine has a single pulley and the original had two, one on each side of the engine. So to proceed ever so carefully and make the final adjustments (and new welds) I will never be able to use the GT for anything but a ’Tug’. This would work just ducky for pull behind, follow me implements, but never again use the mower deck (which I don’t have YET).

I am very seriously considering using the Honda engine as a stationary power source to operate a small hydraulic pump. Oh, yeah…I know, this has been done or attempted before, it‘s not cost effective, routing lines and valves can be problematic, controllers, reservoir tank and other hardware may prove tough to figure. …but did I mention I’m serious? The hydraulic pump could quite adequately power the transmission via pulleys (one from the crankshaft to pump, and one from the pump to transmission pulley) AND also power a small hydraulic motor for the mower deck (which I will probably build myself).

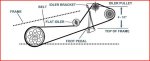

Attached is the original belt and mechanical pulley system that operates everything:

Thanks for looking and any opinions, suggestion and advice greatly appreciated!

Mark

I recently acquired an old GT garden tractor of the late ‘60’s early ‘70’s era. It’s an SS-12 Sears.

My original intentions were to restore the little tractor just for fun but the previous owner did some troublesome and moderately malicious ‘butchering’ while replacing the original Tecumseh 12 HP with a side valve, 10 HP Honda. The frame was the original engine mount with pre-drilled holes to accommodate the stock engine but….Bits were cut with a torch for (unnecessary) clearances and other misaligned, but now, near permanent welds have repositioned the pulley travel-clutch mechanism and engine motor mount plate (also slightly misaligned). This caused the crankshaft pulley to be forever at a kilter to the rest of the pulley drive system….Clear as MUD?

....LOL.

....LOL.OK, just skip everything I said above and understand that I spent several hours with various grinders and cut-off tools to carefully UNDO everything! I am now free to properly locate the correct distances, angles and height of the new (replacement) engine. Only one small problem, this engine has a single pulley and the original had two, one on each side of the engine. So to proceed ever so carefully and make the final adjustments (and new welds) I will never be able to use the GT for anything but a ’Tug’. This would work just ducky for pull behind, follow me implements, but never again use the mower deck (which I don’t have YET).

I am very seriously considering using the Honda engine as a stationary power source to operate a small hydraulic pump. Oh, yeah…I know, this has been done or attempted before, it‘s not cost effective, routing lines and valves can be problematic, controllers, reservoir tank and other hardware may prove tough to figure. …but did I mention I’m serious? The hydraulic pump could quite adequately power the transmission via pulleys (one from the crankshaft to pump, and one from the pump to transmission pulley) AND also power a small hydraulic motor for the mower deck (which I will probably build myself).

Attached is the original belt and mechanical pulley system that operates everything:

Thanks for looking and any opinions, suggestion and advice greatly appreciated!

Mark

(I mean mine, not just your's).

(I mean mine, not just your's).