Hi all. I recently bought a used RTV and have been trying to resolve an issue. Any advice would be appreciated.

Problem: 2007 RTV900 with 1137 hrs only achieves 10 mph top speed in high range on flat/level road. I measured this with a GPS. Medium range also yields 9 mph. It is also very sluggish in all gear ranges; I'm comparing this to another one that I've driven which performs very well.

Diagnostics: Engine RPM was measured at 1350rpm idle and 3100rpm wide open throttle. It fails the workshop manual "Traveling Speed Test". With the unit on jack stands, no-load, low range wheel speed is 124rpm (spec is 126-141 rpm). This verifies that the machine is slower than normal. As a next step, I checked the relief valve pressures. Charge pump relief pressure was measured at 103psi (spec is 75-104psi). Forward relief pressure was 3580psi (spec is 3271-3840psi). Reverse relief pressure was out of spec at 3100psi (spec is 3271-3840 psi).

Attempted solutions: I think I finally managed to get all linkages and cables adjusted; that's another story. Spark arrestor is gone. All fluids and filters changed at 1132 hrs using Kubota brand filters and UDT oil (I know, I'll go back with Super UDT). The reverse relief pressure valve is now set to 3400psi, but that did not resolve the traveling speed issue.

My next guess was that the swash valve plates or the pump cylinder assemblies were worn and were not building enough pressure when loaded. So... I decided to tear into the pumps.

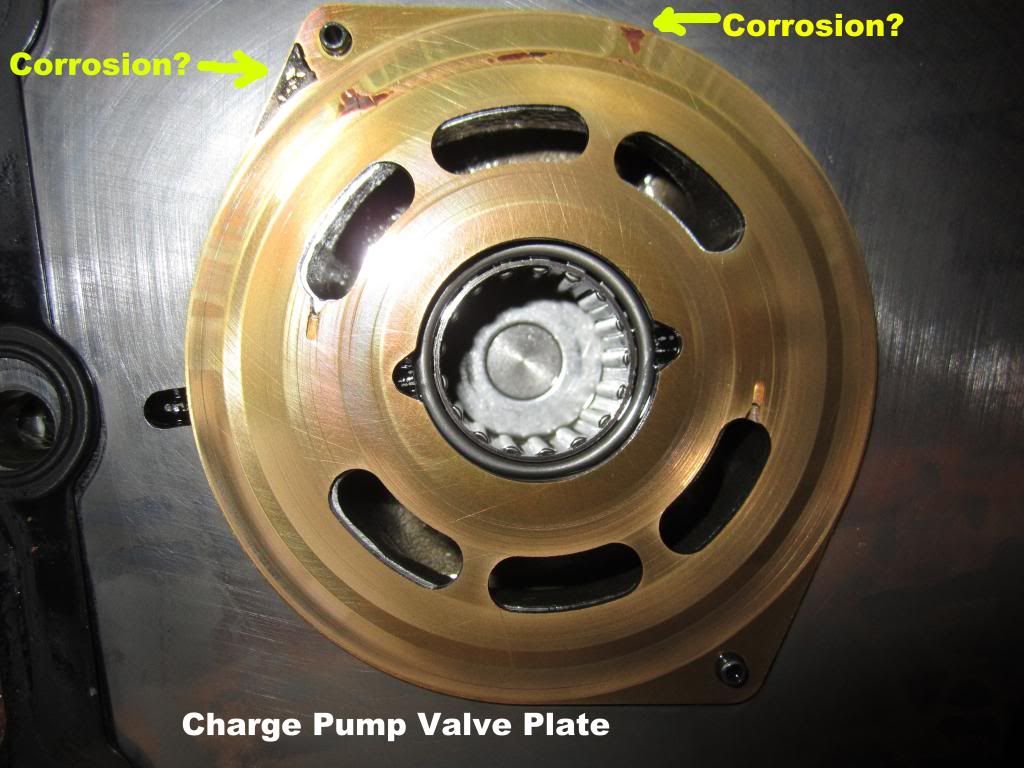

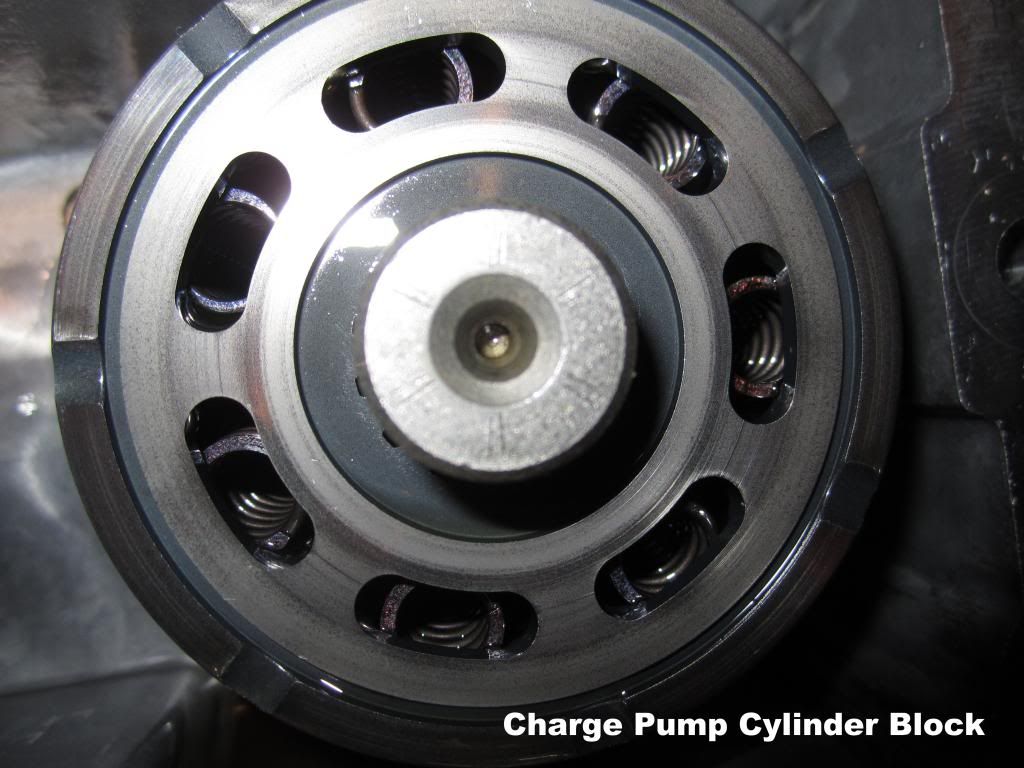

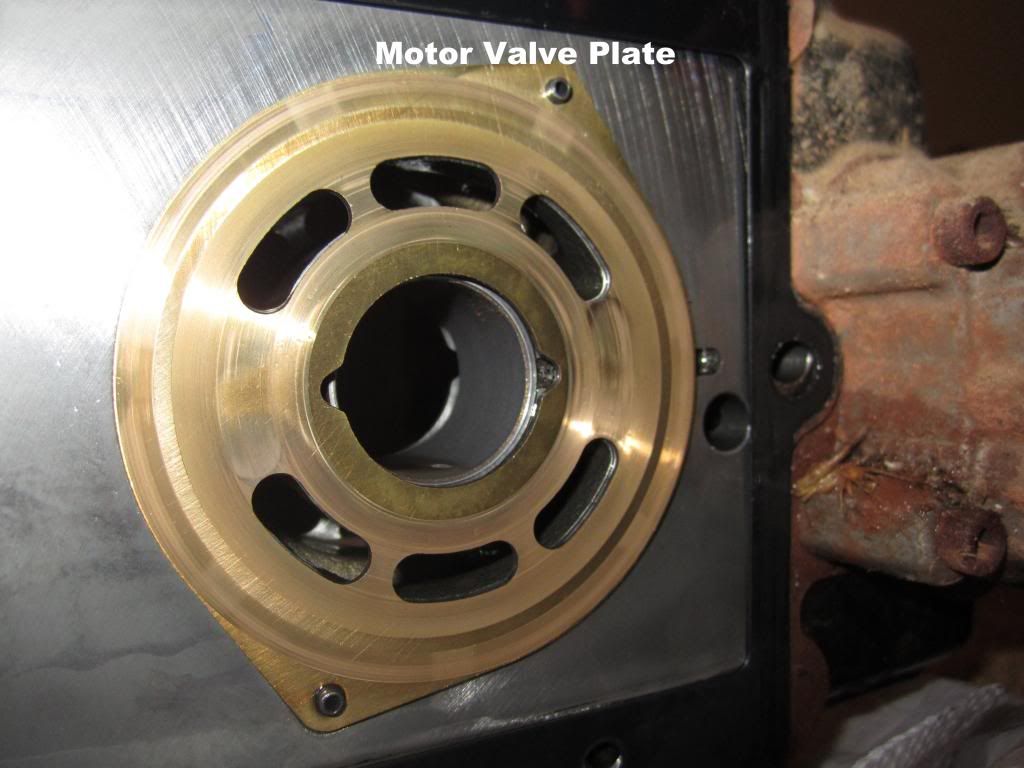

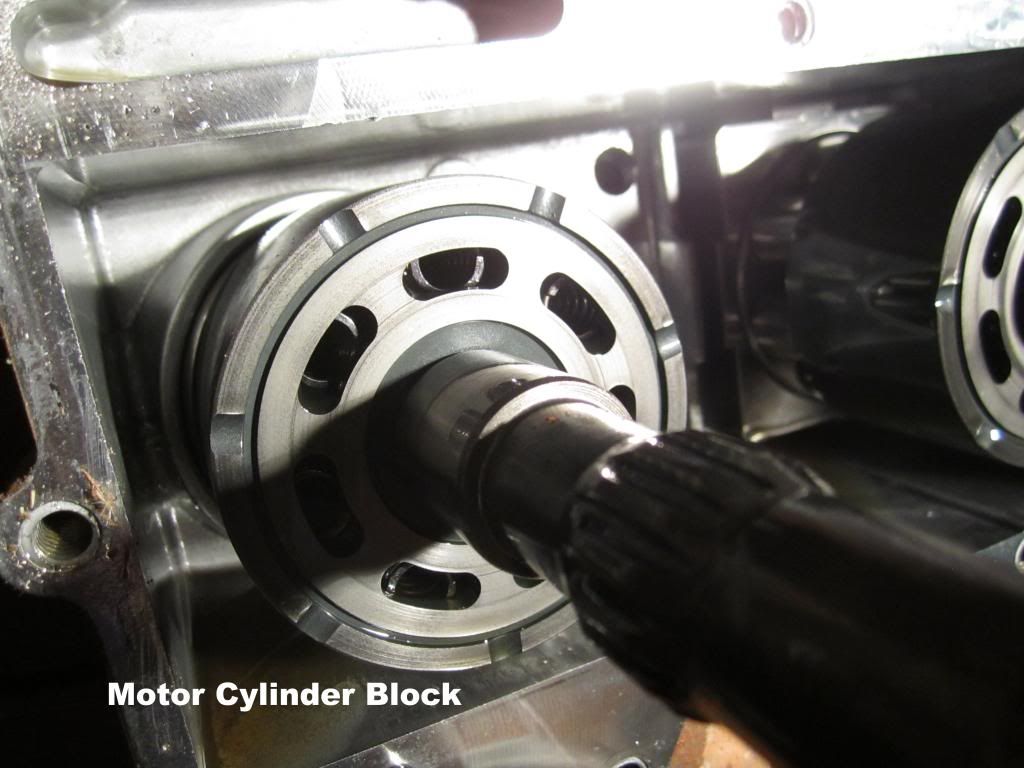

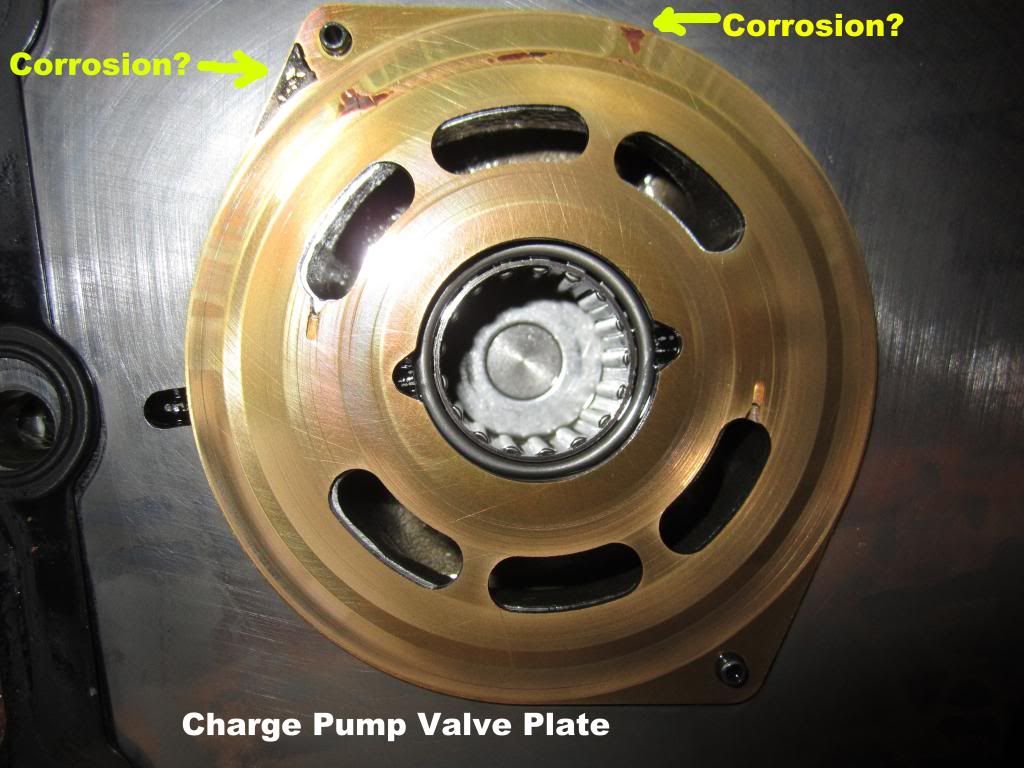

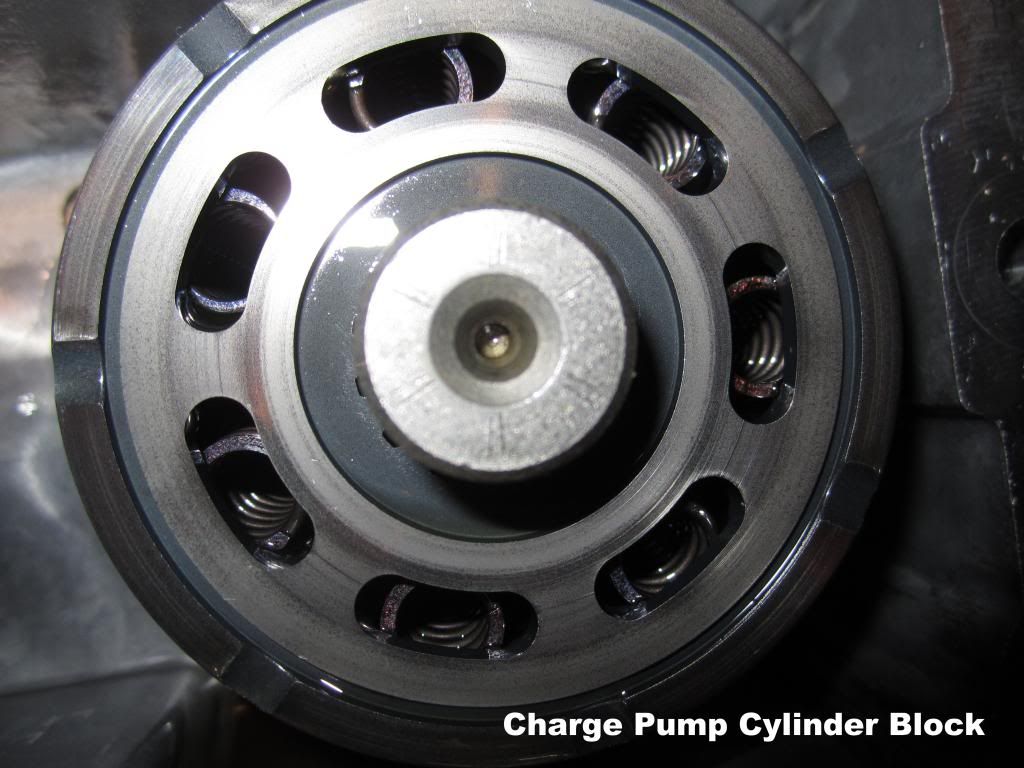

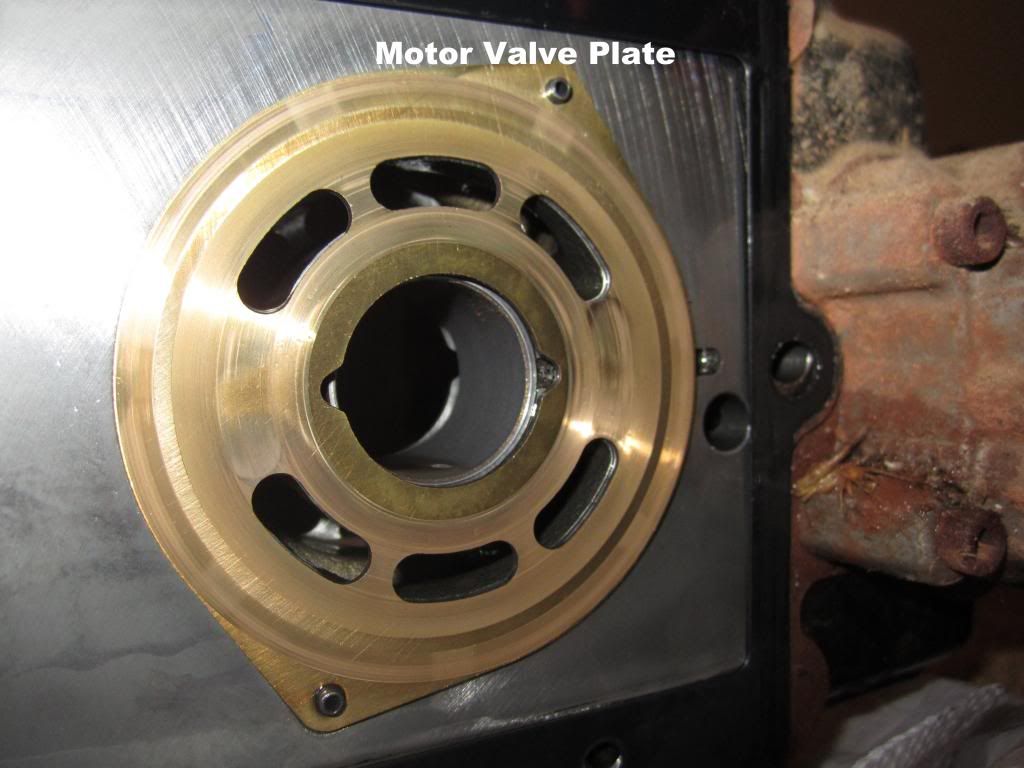

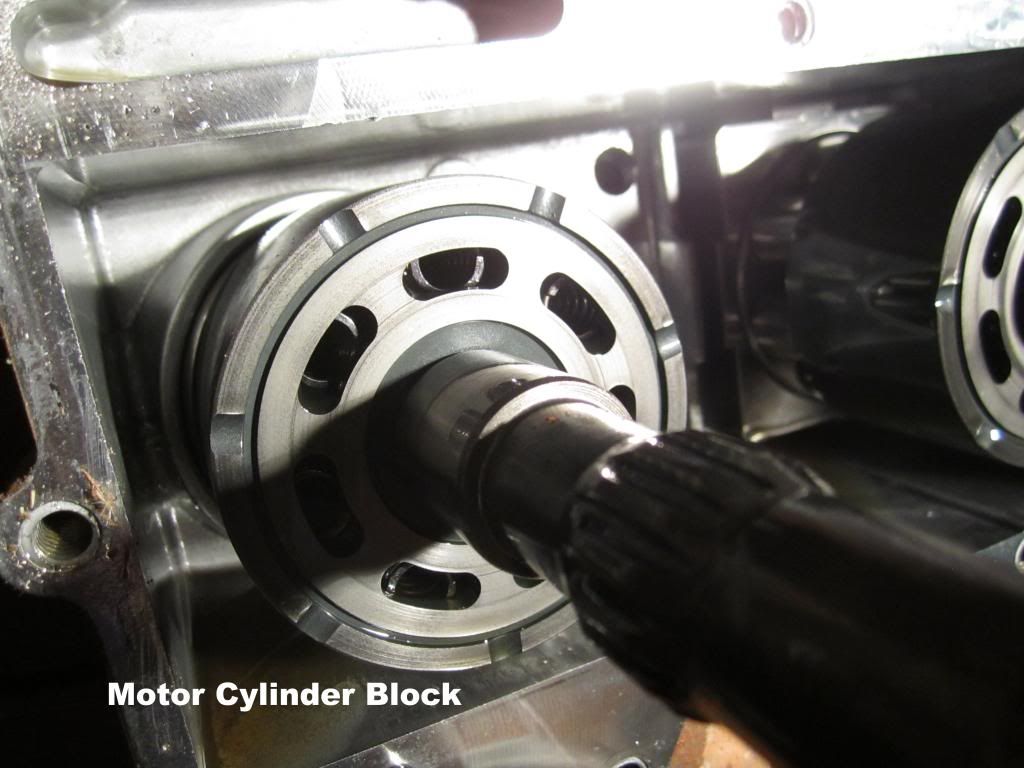

QUESTION 1: How do you know if you need to replace the piston cylinder assemblies? I have included some pictures of my valve plates and cylinder assemblies. Based on the wear marks on the brass swash valve plates, I plan on replacing all three valve plates (charge, motor, assist motor). I figured you could place a straight edge across the cylinder face and measure groove depth, but the workshop manual does not mention an acceptable range.

QUESTION 2: What have I overlooked that would cause 10mph top speed?

Problem: 2007 RTV900 with 1137 hrs only achieves 10 mph top speed in high range on flat/level road. I measured this with a GPS. Medium range also yields 9 mph. It is also very sluggish in all gear ranges; I'm comparing this to another one that I've driven which performs very well.

Diagnostics: Engine RPM was measured at 1350rpm idle and 3100rpm wide open throttle. It fails the workshop manual "Traveling Speed Test". With the unit on jack stands, no-load, low range wheel speed is 124rpm (spec is 126-141 rpm). This verifies that the machine is slower than normal. As a next step, I checked the relief valve pressures. Charge pump relief pressure was measured at 103psi (spec is 75-104psi). Forward relief pressure was 3580psi (spec is 3271-3840psi). Reverse relief pressure was out of spec at 3100psi (spec is 3271-3840 psi).

Attempted solutions: I think I finally managed to get all linkages and cables adjusted; that's another story. Spark arrestor is gone. All fluids and filters changed at 1132 hrs using Kubota brand filters and UDT oil (I know, I'll go back with Super UDT). The reverse relief pressure valve is now set to 3400psi, but that did not resolve the traveling speed issue.

My next guess was that the swash valve plates or the pump cylinder assemblies were worn and were not building enough pressure when loaded. So... I decided to tear into the pumps.

QUESTION 1: How do you know if you need to replace the piston cylinder assemblies? I have included some pictures of my valve plates and cylinder assemblies. Based on the wear marks on the brass swash valve plates, I plan on replacing all three valve plates (charge, motor, assist motor). I figured you could place a straight edge across the cylinder face and measure groove depth, but the workshop manual does not mention an acceptable range.

QUESTION 2: What have I overlooked that would cause 10mph top speed?